As one of the important construction machinery tools, road rollers play a role in applying pressure on surfaces, which helps support the construction process and makes it run quickly and smoothly. To achieve this, have you ever wondered about the structure and operating principle of a road roller? Let’s explore this with Comacpro in the article below.

What is the Structure of a Road Roller?

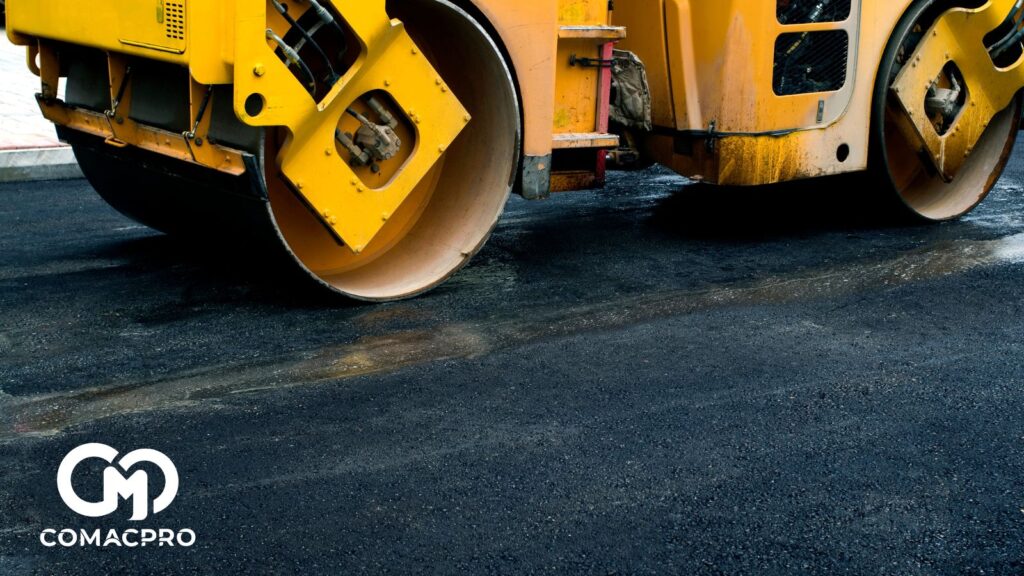

With its main function of compacting and flattening roads, foundations, or construction materials, the design of a road roller is different from regular construction machines. Generally, road rollers have a drum-shaped wheel that helps compress the surface to be compacted.

Depending on the type of roller, it may have one or multiple heavy drums, some weighing several tons. As a result, road rollers move slowly, which is an advantage that helps them perform their best function.

In addition to the prominent roller wheel, road rollers also include other important components such as:

- Chassis: The load-bearing frame made of sturdy steel.

- Control Cabin: The operator’s cabin, which is equipped with control tools and displays to help the driver monitor the condition of the machine and perform necessary operations.

- Filtration System: This includes air filters, water filters, hydraulic oil filters, engine oil filters, etc. Fuel filters clean the fuel and separate any water from the fuel, ensuring the engine operates at optimal power.

- Transmission System: This includes the engine and drive components that help the roller move and operate. The engine can be either diesel or gasoline, depending on the roller type and required power.

- Hydraulic System: Used to control various parts of the road roller, such as the compaction system, water pumps into the roller wheels (in some types of rollers), and adjusting compression pressure.

- Shock Absorption System: Equipped to reduce vibrations and provide stability to the roller during operation.

Operating Principle of a Road Roller

In general, the operating principle of a road roller is quite simple. A road roller works based on the gravitational force of the roller drum, which focuses on compressing and compacting loose, wet, or porous soil or stone layers.

When strong gravitational force is applied, the surface to be compacted becomes solid and flat. This ensures that the ground will not sink when the roller exerts pressure.

Currently, most road rollers operate on the principle of using the gravitational force of the roller drum and the machine itself to compact rough surfaces and make them flat.

The above article introduces the structure and operating principle of road rollers, and we hope this information is useful to you. If you are unsure about choosing construction machinery in general or road rollers in particular, please contact Comacpro’s website for the fastest support and consultation.

Vietnam’s largest equipment purchasing platform – Comacpro

Headquarters: ACCI Building, 210 Le Trong Tan, Thanh Xuan District, Hanoi City

Southern Office: Eco Green Saigon, Nguyen Van Linh Street, Tan Thuan Tay, District 7, Ho Chi Minh City

Northern Hotline: 0865.919.939

Southern Hotline: 0865.1515.06

Email: [email protected]

Website: https://comacpro.net

Youtube: https://www.youtube.com/@ComacProOfficial